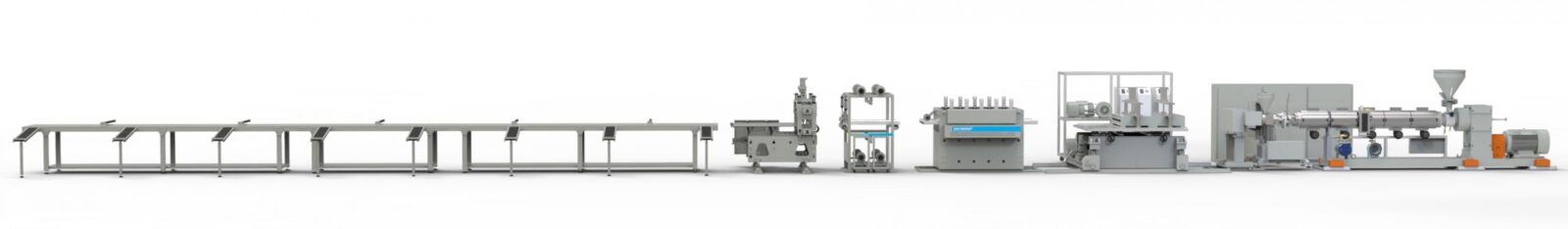

Hollow Profile Pc Line

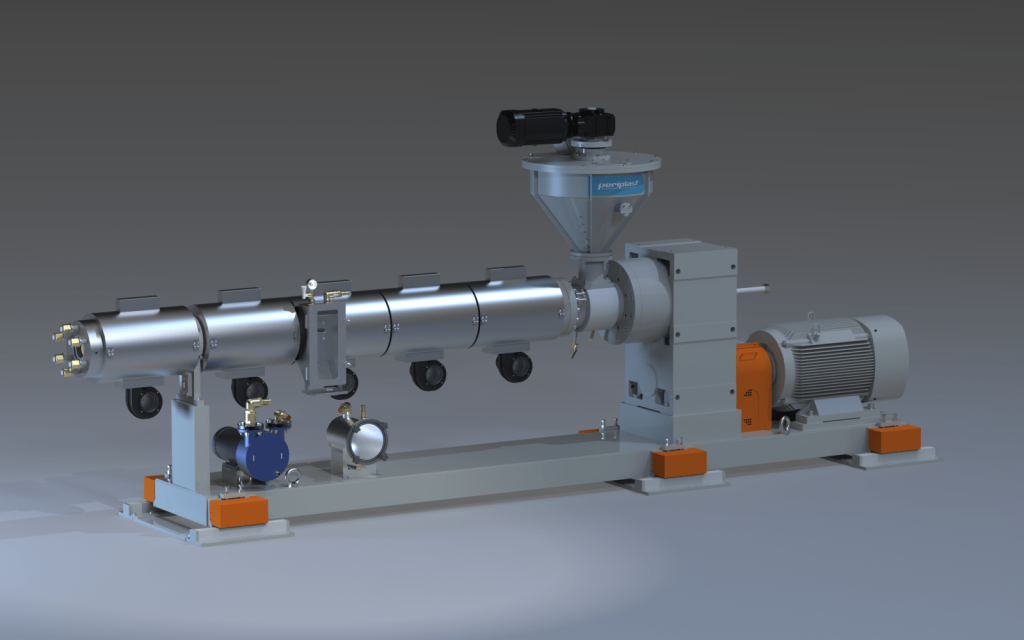

100x35d single screw extruder with high performance PC screw, with degassing (no drying required)

Bimetallic body, hardened and nitrated screw.

UV layer with Co-Extrusion. Plasticizing unit designed for the production of sensitive materials at high rates: flat feed section and high output screw design. Nitrided screw and barrel.

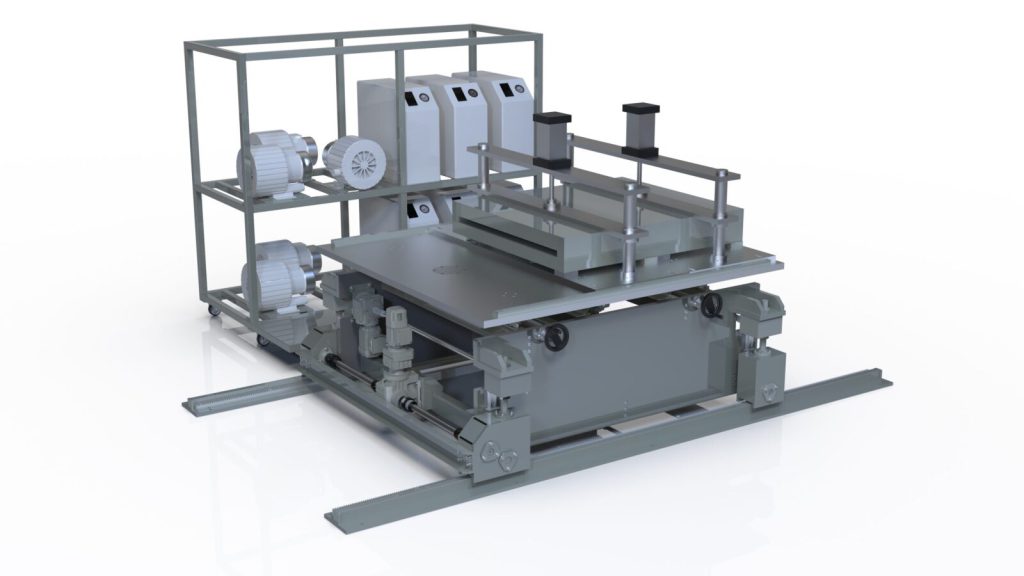

Periplast coextrusion feed blocks have been specifically studied and built to obtain a perfect co-ex distribution with the aim of reducing downtime for production changes.

The feeding block is composed of two parts: the rear part is connected to the extruders, the front part is connected to the die and they are joined by a jaw coupling cone that allows to perform a quick replacement of the die.

Co-ex configuration changes are also possible by simply changing inserts in the power block, no extra operation is required.

Calibrators are designed, developed and produced to handle any specific PC production requirement.

In addition, for the production of diversified corrugated solid profiles, replacing the standard gauges for each specific profile, a new special “tool” was developed that allows the production of different formats without the need to replace the gauges; the only replacement required is disconnecting and connecting the “tool” specific small parts (inserts).

The Puxo is composed of two main independent parts: the lower part and the upper part of the body.

This configuration can handle different typologies of similar PC products.

Additionally, the upper body can be easily replaced to handle an even wider range of PC products.

Construction features and specific operation:

-for multiwall panels and sheet products: a thin blade

-for solid corrugated profile: a guillotine blade

Both systems can be installed on the same cutting machine.

With our software it is possible to control in real time every detail of the production line.

With these solutions, it is possible to run the line with minimal operator intervention and, due to the optimum accuracy, raw material waste is substantially reduced.

Easy remote access means issues can be resolved anytime, anywhere.

It is also possible to integrate with databases for reporting and analysis.

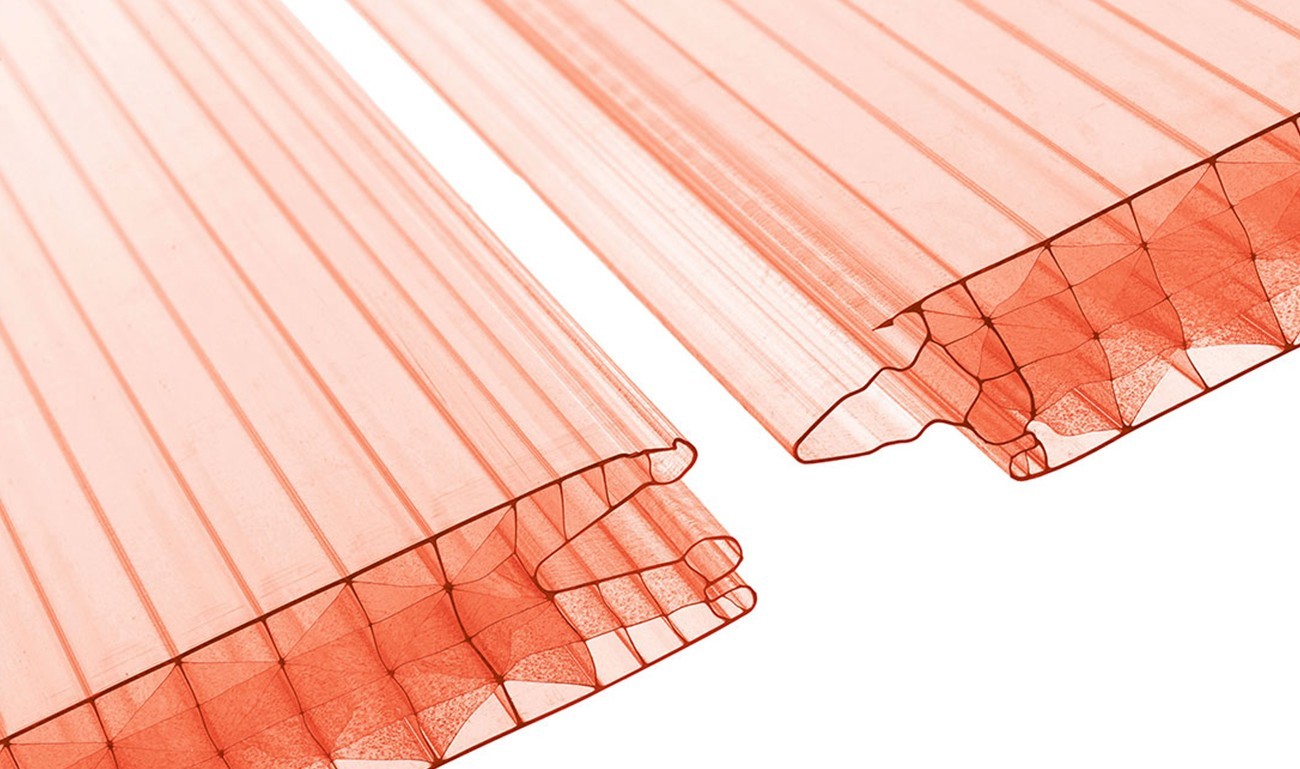

Rigid frame plates with a variety of light transmission options and excellent thermal insulation

Corrugated honeycomb polycarbonate sheets have at least two faces. This creates insulating air spaces (cells) that help reduce heat transfer and results in a rigid, impact-resistant sheet that is significantly lighter than solid sheets of polycarbonate, acrylic or glass. Furthermore, this solution offers substantially better energy efficiency than any single ply sheet. The honeycomb polycarbonate product line offers many options – from integrated condensation control to greenhouses and garden centers that reduce solar heat gain and provide greater light transmission and clarity.

Receive all the news regarding new products and development

Phone (351) 244 859 990

Email: comercial@periplast.pt

Address Rua dos Marrazes, Lote 32

Zona Industrial Cova das Faias

2415-807 Leiria