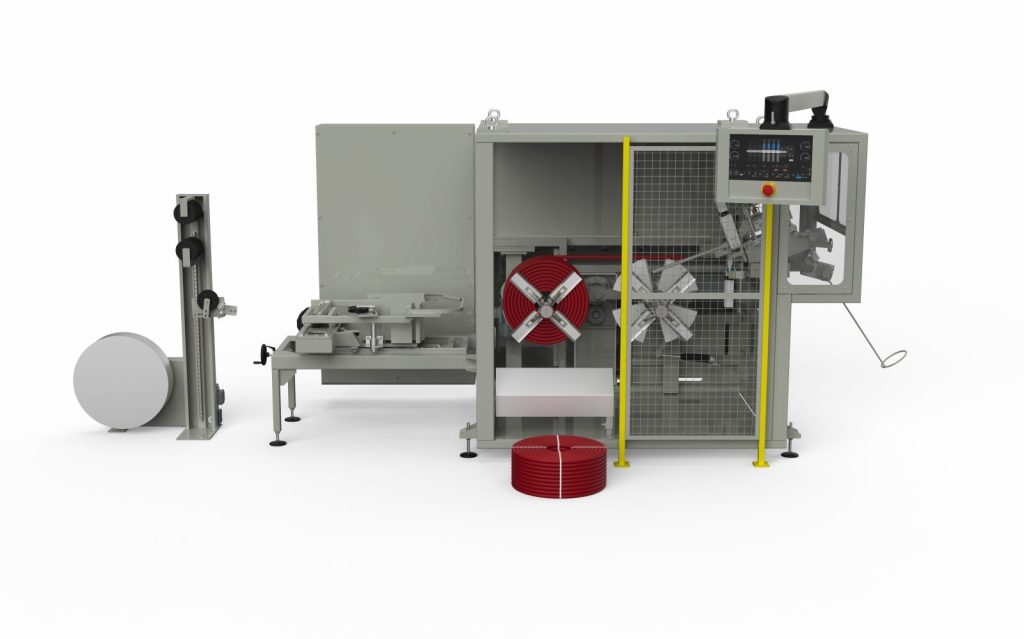

Each coiling station is supported by the same arm that switches between coils, at the end of each coil;

At the end of each coil, the equipment makes the switch between one matrix (die) and the next, makes the cut in the new matrix starting in the new coiler without operator intervention. It is up to the operator to strap and remove the first coil (release of the coil controlled by the operator – pneumatically);

Coil tension control ( coiling tension and maximum tension);

Pneumatic positioning system of the winder arms that define the width of it. Linear coiling (winding) speed synchronized with the extrusion speed;

Distributor driven by motor;

Digital control of the coil dimensions;

Total control of the coiling through PLC which registers production statistic data;

Generation and control recipes for the various items, varying hose diameter, thickness and length of the coil;

Operation in automatic mode.

| MODEL | Hose ID range [mm] | Hose OD range [mm] | Coil dimensions range [mm] | Maximum linear speed [m/min] | ||

|---|---|---|---|---|---|---|

| ID | Max. OD | Width (depth) | ||||

| BTM70 | Ø9 to Ø32 | Ø12 to Ø40 | 160-300 | 700 | 130-300 | Up to 60 |

Contact us for more details and a customized quote.