Periplast at the Plastics Recycling Show Europe 2023, Amsterdam

A Periplast marcou presença como empresa expositora numa das principais feiras europeias do sector dos plásticos e da reciclagem, em maio de 2023. Participar na

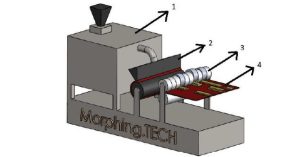

The plastic extrusion line is essential equipment for the production of various technical materials, such as tubes, profiles, sheets and wires. With the aim of making production more efficient and sustainable, the plastic extrusion line that recovers production surpluses is the ideal choice.

This extrusion line is capable of recovering technical materials of different types, such as PE, PP, PVC, ABS, among others. This allows the company to recover and reuse production surpluses, which helps to reduce raw material waste and production costs.

Another important feature of this equipment is the circulation of water in a closed circuit. This means that water is recycled and reused, which contributes to reducing water consumption and environmental impact. Furthermore, water level control is automatic, which guarantees safer and more efficient operation.

Finally, the thermal insulation of the plasticization set is another feature that contributes to the efficiency and sustainability of the extrusion line. This allows the temperature to be kept stable throughout the production process, which guarantees the quality of the technical materials produced and also contributes to reducing energy consumption.

In summary, the plastic extrusion line that recovers production surpluses is an ideal option for companies looking to produce more efficiently and sustainably. With the ability to recover various technical materials, water circulation in a closed circuit, automatic water level control and thermal insulation of the plasticization set, this extrusion line is a safe and efficient option that contributes to reducing environmental impact and production costs.

A Periplast marcou presença como empresa expositora numa das principais feiras europeias do sector dos plásticos e da reciclagem, em maio de 2023. Participar na

A linha de extrusão de plástico é um equipamento essencial para a produção de diversos materiais técnicos, como tubos, perfis, folhas e fios. Com o

O projeto em questão tem como objetivo principal produzir painéis poliméricos multicamada de espessura variável, os quais podem ser compostos por diferentes tipos de polímeros,

Receive all the news regarding new products and development

Phone (351) 244 859 990

Email: comercial@periplast.pt

Endereço: Rua dos Marrazes, Lote 32

Zona Industrial Cova das Faias

2415-807 Leiria